Dans un contexte où l’espace, la sécurité et la productivité dictent la performance logistique, le racking industriel devient un levier stratégique pour tout entrepôt. Une structure de palettier bien conçue permet d’entreposer les palettes, d’optimiser la gestion des flux, d’accélérer la préparation de commandes et d’améliorer l’efficacité d’entrepôt.

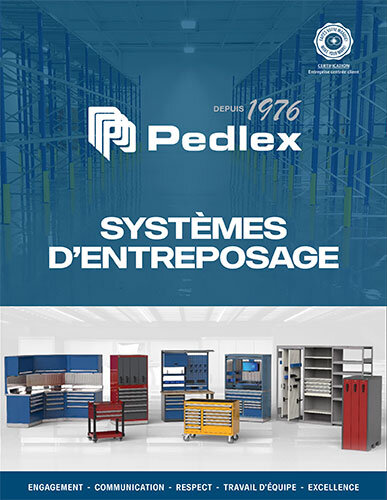

Chez Pedlex, entreprise québécoise spécialisée en solutions d’entreposage, nous concevons et installons des racks d’entrepôt adaptés aux besoins spécifiques de chaque organisation. Nos systèmes de rangement industriel sont pensés pour maximiser la performance opérationnelle, assurer la durabilité des installations et respecter les normes canadiennes en vigueur, incluant la conformité CNESST Québec.

Des systèmes de racking industriel conçus pour la performance

Nos rayonnages à palettes industriels sont conçus selon les dernières normes parasismiques et scellés par ingénieur, garantissant un rangement industriel lourd à la fois sécuritaire et durable. Avec nos racks industriels, palettiers ou rayonnages en porte-à-faux pratiques et économiques, vous optimisez l’utilisation de votre espace de stockage tout en améliorant votre environnement de travail. Nos experts en conception et installation de systèmes de rangement industriel vous aideront à obtenir une meilleure gestion de votre capacité de stockage, en livrant le rayonnage qui correspond précisément à vos besoins et à l’espace disponible. Nos gammes de services complètes incluent la consultation, le design, l’installation, la réparation et la certification des palettiers.

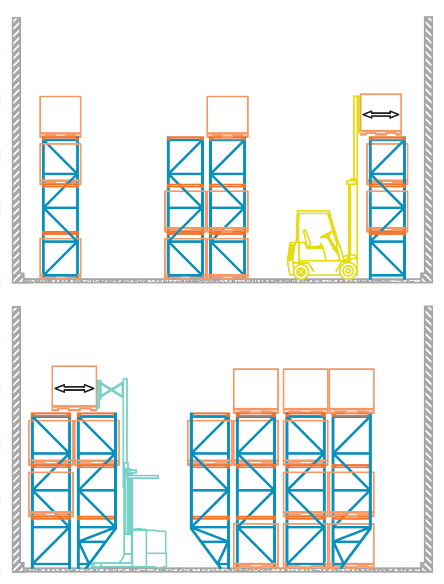

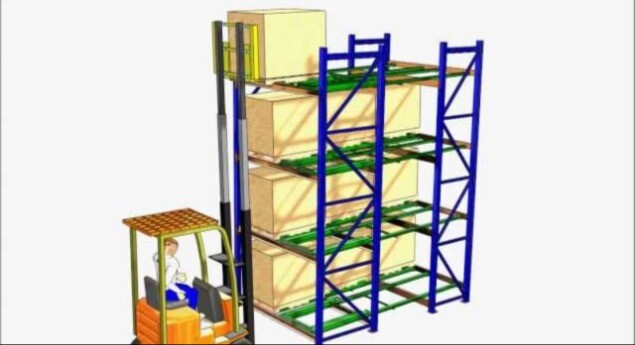

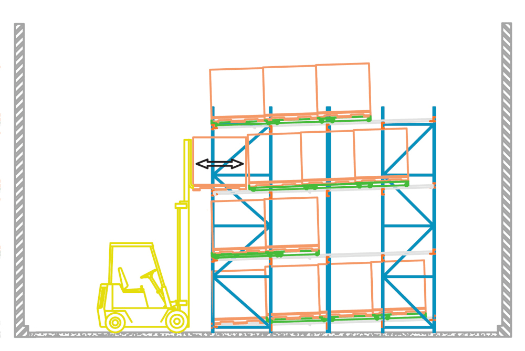

Chaque système d’entreposage industriel est conçu en fonction de la capacité de charge par niveau, de la charge admissible, de la hauteur libre d’entreposage et de la configuration des allées. Cette approche permet d’assurer une compatibilité optimale avec les chariots élévateurs, tout en améliorant la circulation interne et la sécurité des opérations.