Explore Our Expertise in Turnkey Pallet Racking Solutions

Pedlex has been your expert in turnkey pallet racking systems since 1976. Our wide variety of industrial pallet racks are designed and sealed by engineers according to the latest anti-seismic codes and norms, ensuring heavy-duty pallet racks that offer safe and durable storage. Whether you’re expanding your warehouse, building a factory, or relocating your business, our solutions help you optimize your space and secure your premises.

With practical and economical designs, our variety of pallet racking systems improve your working environment by maximizing floor space and vertical space, increasing your overall storage capacity. Take advantage of our complete turnkey service, from consultation and design to installation, repair, and certification of pallet storage racks.

Maximize Your Warehouse Space with Industrial Pallet Racking

Our pallet racking systems are designed to make the most of your available warehouse space, improving access and enhancing safety. Whether it’s storing bulky items or lighter items, Pedlex offers custom configurations that fit your storage requirements. With solutions like selective racking, push-back racking, and pallet flow systems, we ensure your inventory is stored efficiently and accessed safely.

Customizable Pallet Racking Solutions to Meet Your Needs

At Pedlex, we offer both pre-designed pallet rack units and fully customizable solutions. Our versatile teardrop pallet rack design allows for easy reconfiguration and growth, ensuring that your storage evolves with your business.

We also specialize in structural steel pallet racks for high-performance environments where heavy lifting and frequent forklift impacts are common. These racks are ideal for storing heavy loads and maintaining the structural integrity of your storage system.

Pallet Rack Systems: The Pedlex Advantages

A supplier of industrial pallet racks since 1976, we offer rack shelving or racking with single or double depth, as well as reverse gravity (push back) systems. Pedlex’s specialized solutions include standard and restricted aisles, in structural steel, static accumulation systems (drive-in), dynamic accumulation systems (pallet flow), as well as safety accessories – protective mesh, safety bars, end of aisle protectors, steel upright protectors and Rack Armor, etc.

With over 45 years of experience, Pedlex ensures that every racking system we deliver is tailored to meet your unique storage requirements, maximizing your warehouse’s efficiency. Our solutions come with various lengths and weight capacities. Contact our experts today for a consultation and benefit from a personalized solution that fits your space and your budget!

Pedlex Pallet Racks: Practical, Safe, and Cost-Effective

Optimize Vertical and Floor Space

Our pallet racks are designed to take full advantage of both vertical space and ground level, increasing the total storage capacity without requiring additional square footage. With our solutions, the height of the storage levels is adjustable.

Safety Features and Durability

We prioritize safety by designing steel pallet racks that meet CNESST standards, including features like upright columns, column protectors, and row spacers to minimize the risk of accidents. Our racks are built to withstand forklift collisions, ensuring both durability and easy maintenance.

Fast and Easy Installation

Our bolted pallet racking systems, like the NuvoRack, are easy to assemble, modify, and maintain. This flexibility allows for quick adjustments based on your evolving storage space needs, and our trained technicians can install these systems throughout Montreal and Quebec.

Pedlex: Comprehensive Services and Expertise

Our services include consultation, installation, relocation, repair,

and inspection and certification of pallet racks.

Discover the benefits of our Nuvorack certified bolted pallet racking below,

which are made in Quebec.

Contact Pedlex experts to obtain a quote that meets your needs and benefit

a personalized turnkey service. Our project managers will support you during the design

to help you make a choice that meets your needs. Our trained and certified installation teams

deliver and install everywhere in Montreal and Quebec.

Types of Industrial Pallet Racking Systems We Offer

Single and double depth

Single and double depth

Restricted aisle

Restricted aisle

Structural steel

Structural steel

Static accumulation (drive-in)

Static accumulation (drive-in)

Reverse gravity (push back)

Reverse gravity (push back)

Dynamic accumulation (pallet flow)

Dynamic accumulation (pallet flow)

At Pedlex, we offer a wide range of pallet racking systems designed to meet the diverse needs of warehouses and industrial facilities. Whether you require high-density storage, quick access to products, or enhanced safety features, we have the solution to fit your storage requirements.

Selective Pallet Racks

Single and Double Depth Pallet Racks

Our selective racking systems – single and double-depth pallet racks, are among the most popular choices on the market. The forklift aisles are configured between back-to-back rows of pallet storage or industrial shelving. Our racks provide easy access to every pallet, ensuring flexibility and ease of use. Available in single or double-depth configurations, selective pallet racks offer superior storage capacity and can be paired with various pallet racking accessories, such as wire mesh decking, various beam profiles, and additional bracing for enhanced stability.

They are economic and offer excellent selectivity and versatility. The choice depends on the amount of storage density you need – single depth provides low density, and double-depth offers good density, but requires double-reach lifts.

Restricted aisle pallet rack (single depth)

Same as single-depth pallet racking, but use a narrow isle forklift, reducing aisle width and optimizing use of storage space.

Structural Steel Pallet Racking

Structural Steel Pallet Racking

The ideal solution for businesses requiring heavy-duty and durable solutions; our structural steel pallet racks are built to withstand the toughest environments. These metal pallet racks are perfect for high-performance storage systems, especially in environments with frequent forklift traffic or heavy lifting requirements. The structural end-frames and roll-formed beams ensure these racks can handle heavy loads and resist impacts. The joists are joined using 4 grade 5 nuts and bolts, 1/2″ x 1″. A few advantages include:

- Superior Durability: These racks are designed for environments that experience repeated forklift impacts.

- Load Capacity: Ideal for storing heavy-duty items and supporting high-density storage needs.

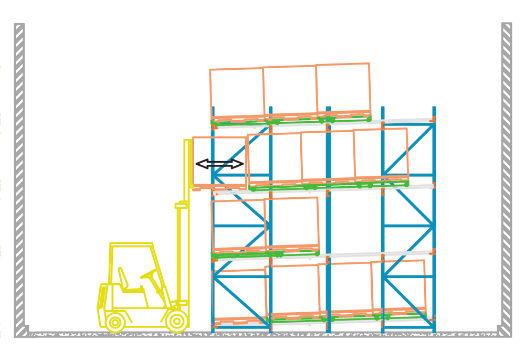

Push-Back Racking System (Reverse gravity system)

Push-Back Racking System (Reverse gravity system)

Our push-back racking is designed to optimize density pallet rack storage by allowing pallets to be stored multiple pallets deep on mobile carts. The Push-Back Rack design reduces forklift aisle space, making it perfect for warehouses aiming to maximize storage racks while maintaining ease of access. It offers faster loading and unloading compared to other high-density storage solutions. The advantages:

- High Selectivity and Density: Each level holds multiple pallets deep, allowing for excellent selectivity while maximizing storage capacity.

- Efficient Loading/Unloading: Pallets move forward automatically as each one is removed, reducing forklift travel time.

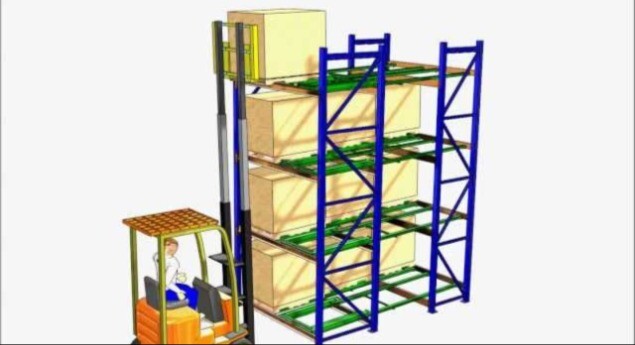

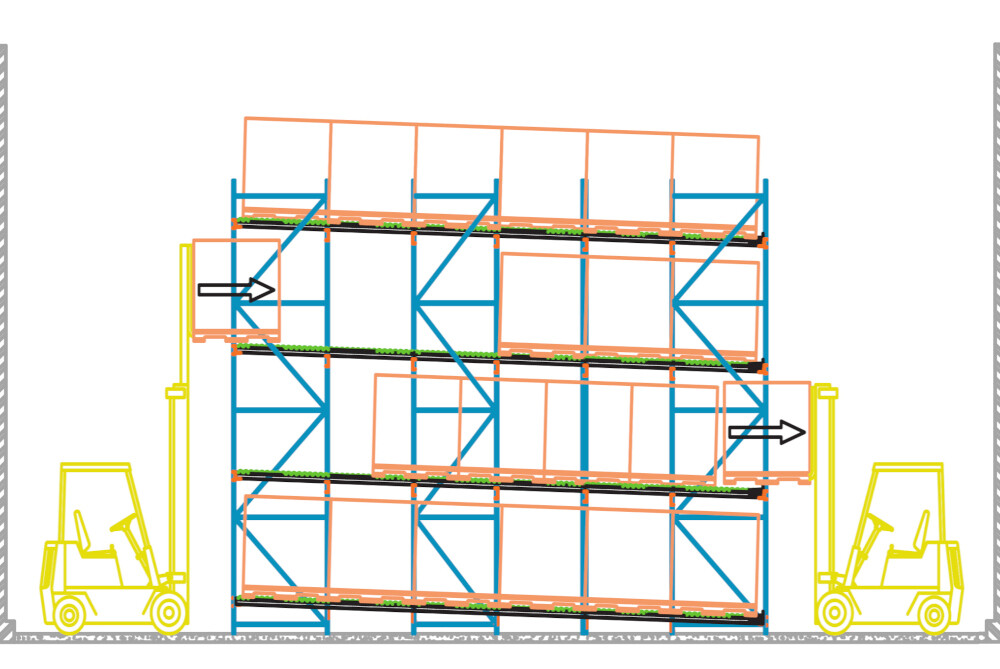

Pallet Flow Racks or Carton Flow (Dynamic Accumulation System)

Pallet Flow Racks or Carton Flow (Dynamic Accumulation System)

Carton Flow is a pallet flow racking system that allows you to load pallets on one side and unload them on the other, allowing you to always take the first one that comes into inventory, for easy FIFO applications and management (first-in, first-out).

Advantages:

- FIFO Rotation: Ensures that the first pallets loaded are the first to be picked, ideal for managing perishable goods or time-sensitive products.

- High Density: Maximizes storage space while maintaining accessibility.

Static accumulation (drive-in)

Static accumulation (drive-in)

Our drive-in racking system is an ideal solution for high-density storage where selectivity is less critical. This static accumulation system allows forklifts to drive directly into the rack’s storage lanes, storing pallets in a deep configuration. The drive-in system is highly efficient for warehouse racking that needs to accommodate heavy loads and reduce forklift aisle space. The advantages:

- Maximized Storage Density: Allows deep storage of pallets in a single lane, ideal for bulk storage of uniform products.

- Efficient Use of Horizontal Space: Eliminates the need for multiple aisles, increasing the overall storage capacity.

- Cost-Effective: Ideal for businesses seeking a high-density storage solution without the need for complex pallet rotation.

What are the advantages of our NuvoRack pallet racks?

The many advantages of our NuvoRack pallet racks, in stock at Pedlex and available for rapid delivery and installation in Montreal and Quebec

NuvoRack pallet racks are in stock at Pedlex, offering the fastest option for rapid delivery and installation in Montreal and throughout Quebec.

- PRACTICAL: Our pallet racks offer ease of shipping, delivery and assembly. Also, they offer ease of modification and reorganization of the initial infrastructure.

- FAST: The ease of intervention on bolted pallet racks allows us to respond faster to any request for installation, repair or reorganization of the structure.

- SAFE: Accidentally, forklifts can hit ladders, rails or uprights. Even if these shocks may seem harmless, they can cause an imbalance or a defect in the part causing, in the medium or long term, premature and dangerous wear.

- MADE TO LAST: Bolted systems allow for the immediate replacement of the part concerned with great ease, thus restoring the stability and security sought after to the system.

- ECONOMIC: These advantages, both practical and safe, allow a reduction in intervention, handling, and maintenance costs.

How to choose the right type of storage system according to your needs and budget?

To choose the right storage system for your needs and budget, consider factors such as the load size you need to store, the amount of horizontal space available, and whether you require additional storage on upper levels. Pedlex offers an extensive range of warehouse racking options, including selective racks, which are ideal for accessible and efficient storage solutions.

Different types of racks, such as pallet racks or shelving systems, can be customized to provide the perfect pallet rack storage solutions for your specific requirements, maximizing both vertical space and horizontal space while optimizing your budget.

| EN STOCK - RAILS (12" DE HAUT) | LONGUEUR NOMINALE | LONGUEUR RÉELLE | POIDS | MODÈLE # |

|---|---|---|---|---|

| 2 pi Traverse de garde-fou robuste | 2'-0" | 1'-7" (19") | 19 lbs | GR2 |

| 3 pi Traverse de garde-fou robuste | 3'-0" | 2'-7" (31") | 25 lbs | GR3 |

| 4 pi Traverse de garde-fou robuste | 4'-0" | 3'-7" (43") | 32 lbs | GR4 |

| 5 pi Traverse de garde-fou robuste | 5'-0" | 4'-7" (56") | 38 lbs | GR5 |

| 6 pi Traverse de garde-fou robuste | 6'-0" | 5'-7" (67") | 45 lbs | GR6 |

| 7 pi Traverse de garde-fou robuste | 7'-0" | 6'-7" (79") | 50 lbs | GR7 |

| 8 pi Traverse de garde-fou robuste | 8'-0" | 7'-7" (91") | 59 lbs | GR8 |

| 9 pi Traverse de garde-fou robuste | 9'-0" | 8'-7" (103") | 67 lbs | GR9 |

| 10 pi Traverse de garde-fou robuste | 10'-0" | 9'-7" (115") | 72 lbs | GR10 |

*LIFO = last in, first out; FIFO = first in, first out

Pallet Rack: Employer Responsibilities for Health and Safety Compliance

As an employer, you are obliged, according to the laws applied by the CNESST, to take measures necessary to protect health and ensure safety and the physical integrity of your people – which includes the compliance of your storage systems, pallet racks, shelves, etc. to current standards and laws.

In particular, in terms of prevention, your responsibility includes:

- take care of occupational health and safety

- identify, correct and control risks in your establishment

- ensure that your premises are set up and safely equipped

- establish a prevention program, if necessary.

Contact Us for Your Turnkey Pallet Racking Solution

Pedlex offers industry-leading solutions for your pallet racking needs. Contact us today to learn more about our custom pallet racking systems, and let our team of experts help you maximize your industrial warehouse pallet space with safe, efficient, and durable storage solutions. We proudly serve businesses throughout Montreal and Quebec.