Why Choose Cantilever Racking for Your Storage Needs?

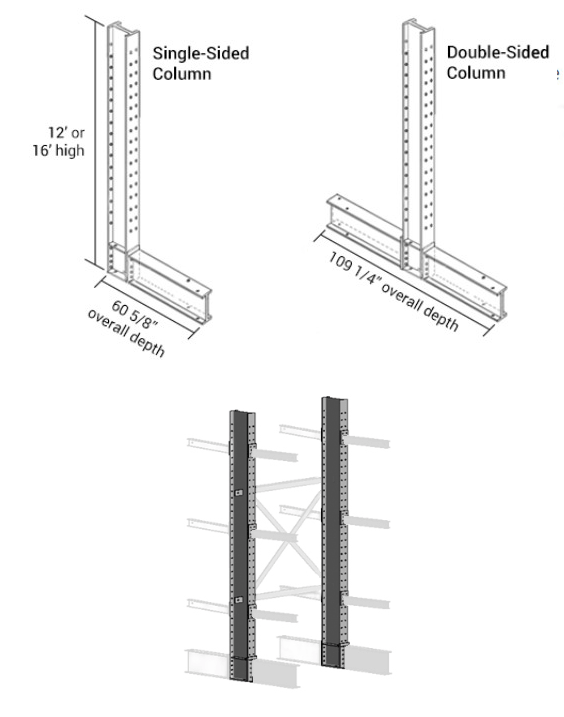

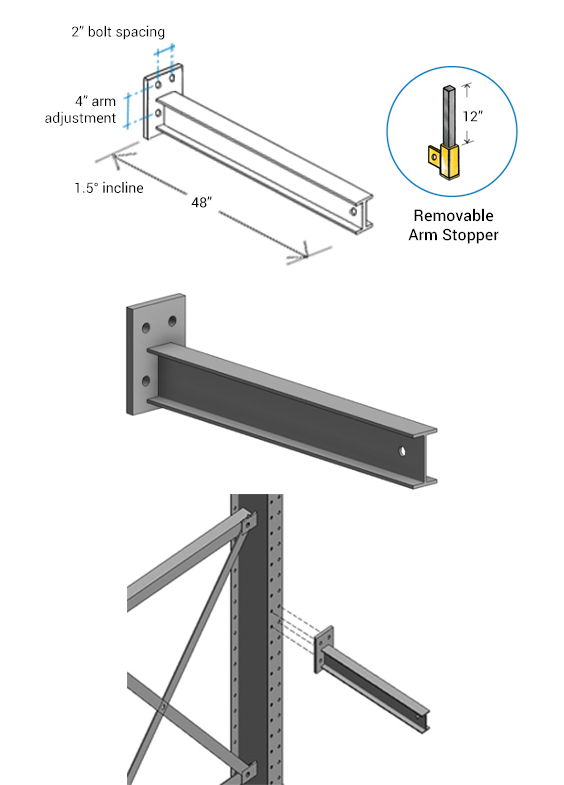

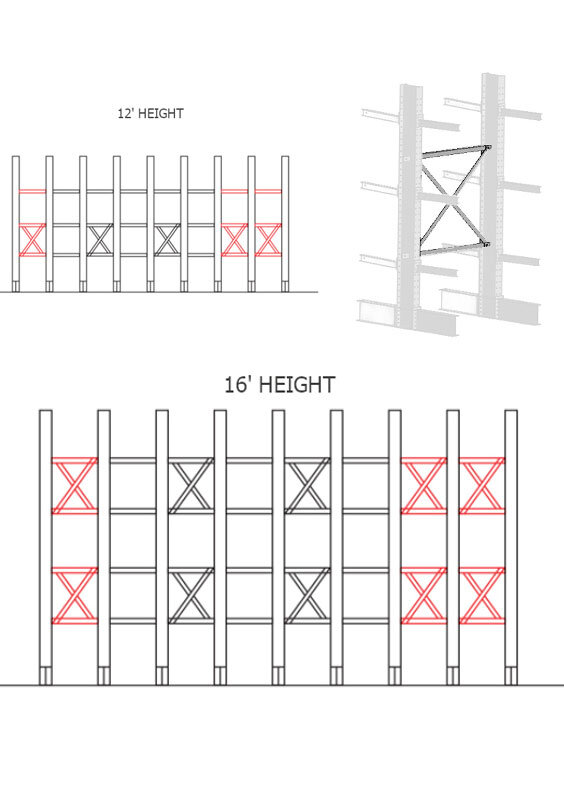

Our cantilever racking systems are exclusively designed and manufactured to rival even the most durable heavy-duty solutions that are available on the market.

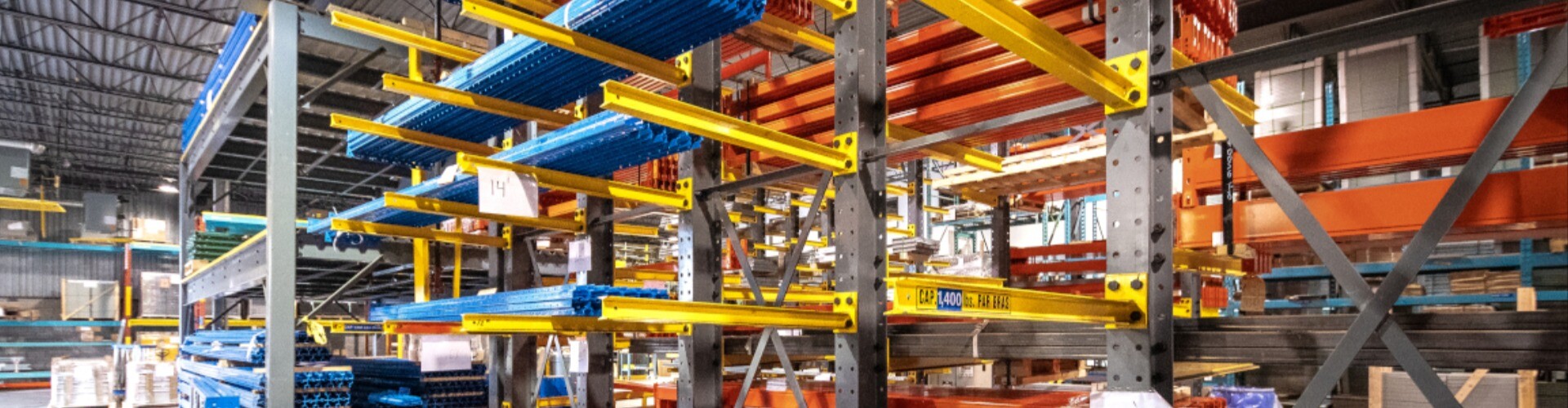

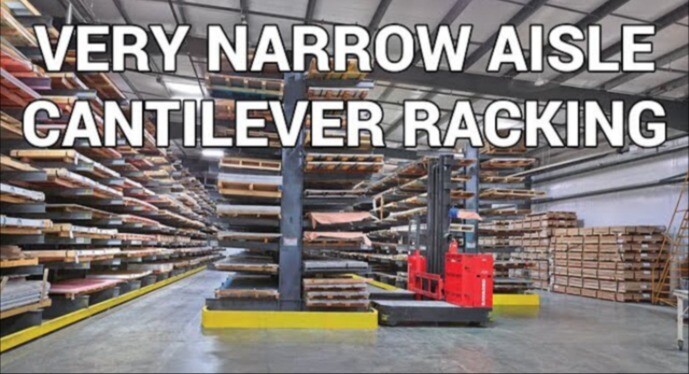

Ideal for storing long or unusually shaped products such as sheet steel, drywall, timber beams, and steel bars, these fully modular systems are engineered according to your specifications, providing you with safe, clear access to your merchandise.

With a wide range of configurations available, our cantilever storage racks can accommodate heavy materials while maximizing floor space. These systems are particularly useful in lumber yards, construction materials storage, and industrial warehouses where bulky items need to be organized efficiently for storage for materials.